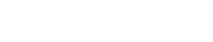

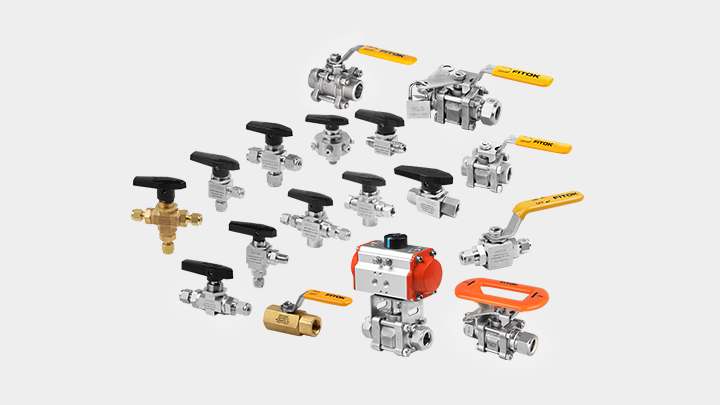

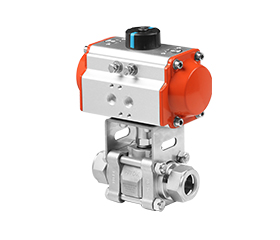

FITOK offers a wide range of ball valves designed for various functions, including CNG/NGV applications, hydrogen applications, and fire-safe ball valves. These valves are available in different body materials, connection types, sizes, orifices, flow patterns, and actuation modes to meet the diverse requirements of fluid systems.

Cookie Notice and Disclosure

FITOK USE OF COOKIES AND SIMILAR TECHNOLOGY

Like many companies, FITOK Group, its subsidiaries and its authorized sales and service centers (collectively, "FITOK" or "we, " "us, " or "our") use "cookies" and similar tools on fitok.com and any authorized sales and service center website (collectively, the "Sites") to facilitate and improve your online experience. This Notice explains how we do that.

What are cookies?

A cookie is a small file or piece of information which is downloaded to your computer or device when you visit the Sites, and then sent back to the Sites in order to allow us to recognize your computer or device later. Although certain cookies may contain personal data – for example, if you click to "remember me" when logging in, a cookie may store your username – most cookies won’t collect personal data that identifies you. Rather, most cookies collect general information, such as how users arrive at and use the Sites, or a user’s general location. By collecting this information, cookies help to analyze web traffic and allow web applications to respond to you as an individual. The web application can tailor its operations to your needs, likes and dislikes by gathering and remembering information about your preferences.

How do we use cookies?

Our Sites utilize cookies for several purposes, including the storage of information required to determine how to properly deliver content to your computer or device. A cookie is provided to all visitors to fitok.com, regardless of whether you register with an authorized sales and service center.

For users who do register with an authorized sales and service center, a profile containing the registration information is generated by our website, and used for several purposes:

• to match you with content that is associated with your interests and to direct you to additional resources and tools that can save you time;

• to enable a fast response for service or follow-up request from our website;

• to verify your identity;

• to send you an electronic newsletter, other information and content; and

• to contact you when necessary.

What kinds of cookies do we use?

We may use cookies for a number of purposes:

Session Cookies – These cookies are used 'in-session' each time you visit and then expire when you leave a Site or shortly thereafter. They are not stored on your computer or device permanently, do not contain any personal data and help by minimizing the need to transfer personal data across the internet. These cookies can be deleted or you can refuse to allow their use, but this will hamper the performance and your experience in using the Sites. These cookies also take time stamps that record when you access the Sites and when you leave the Sites.

Tracking Cookies – These cookies enable us to recognize repeat visitors to the Sites. By matching an anonymous, randomly generated identifier, a tracking cookie keeps track of where a user of the Sites came from, what search engine they may have used, what link they clicked on, what keyword they used and where they were in the world when they accessed the Sites. By monitoring this data, we can make improvements to the Sites.

Persistent Cookies – This type of cookie is saved on your computer or device for a fixed period (sometimes for a few hours, sometimes for a year or longer) and is not deleted when the browser is closed. Persistent cookies are used where we need to remember who you are for more than one browsing session. For example, this type of cookie can be used to store your preferences, so that they are remembered for the next visit to the Sites.

Performance or Analytical Cookies – Performance cookies are used to analyze how the Sites are used and to monitor their performance, which allows us to improve your experience in using the Sites. These cookies help us to tailor the content of the Sites to reflect what the Site users find most interesting and to identify when technical issues with the Sites arise. We may also use this data to compile reports to help us to analyze how Sites are used, what the most common issues are and how we can improve the Sites.

Can the Cookies be blocked?

Yes. Most internet browsers are initially set up to automatically accept cookies. You can, however, change your browser settings to block cookies or to alert you when cookies are being sent to your device. There are a number of ways to manage cookies. Please refer to your browser instructions or help screen to learn more about how to adjust or modify your browser settings.

Please be aware that if you disable the cookies that we use, this may impact your experience while on the Sites. For example, some features and services on the Sites may not work properly because we may not be able to recognize and associate you with your FITOK account(s). In addition, the offers we provide when you visit us may not be as relevant to you or tailored to your interests.